Project Timeline, March 2009 – July 2011

The Midline House is a single-story, energy-efficient home nestled into the landscape of rural upstate, NY. The house combines passive solar heat gain, soy-based spray foam insulation, and thermal mass for Ithaca’s cold winters with ventilation and large eaves for cooling in the summer. To supplement these passive strategies, the house is heated by a horizontal geothermal loop and radiant floors. An Energy Recovery Ventilator (ERV) provides fresh air and conserves heat. Locally sourced Hemlock, reclaimed slate, and Forest Stewardship Council (FSC) certified wood products are used throughout the house. The house is also being monitored for performance (Life Cycle Analysis (LCA)), by an extensive controls system with over 20 temperature sensors.

The completed house is tracked below with notes and helpful information:

The walls of the sunroom are lined with reclaimed slate from the roof of a house in western Massachusetts. The floor is constructed with 1-1/2″ of concrete, finished with tile. During the summer the sunroom is largely shaded, but during the winter the low southern sun charges these thermal mass materials. One cold, sunny winter day during construction the sunroom temperature reached 90 degrees while the outdoor temperature was just 15. Using a simple fan, drawing about the same energy as a single light bulb, heat from the sunroom can be distributed into the house on cold days or exhausted to the outside on warm days. The windows have a high Solar Heat Gain Coefficient (SHGC) and high visible light transmittance.

The great room combines living room, dining room, and custom kitchen under a high roof of locally harvested Hemlock. The floor is half tile, excellent thermal mass, and half bamboo, quickly renewable. The space is heated in winter by a radiant floor and lots of south-facing windows, and stays naturally cool during summer, using passive cross-ventilation and stack-ventilation through the high windows.

With Soapstone countertops, FSC certified cherry and Formaldehyde-free cherry plywood, the custom kitchen elegantly stores everything.

The house is customized with built-ins throughout. The wardrobe has tiered surfaces, drawers, shelves, and clothes hanger for plenty of storage.

The bathroom, lit in part by a skylight to the great room, is entirely custom. The vanity and medicine cabinet is built from rapidly renewable, zero-VOC, FSC-certified bamboo plywood.

One of three bedrooms, the west bedroom has plenty of natural light and a light well for indirect evening lighting.

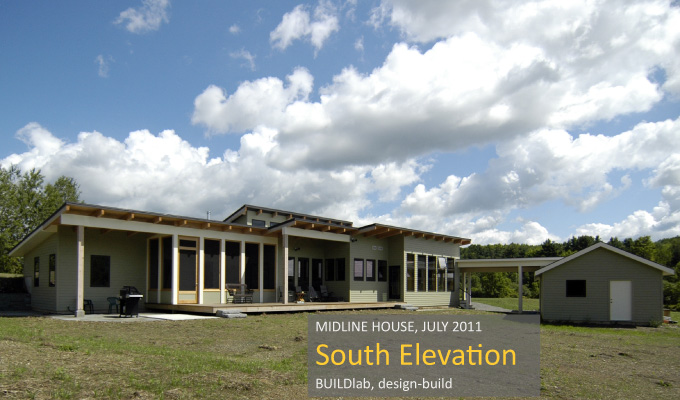

The southern facade of the house features a sunroom, a screened porch, and many windows to optimize solar gain in the winter. The long east-west orientation maximizes exposure to the sun through the entire house over the course of the day. In the hot summer, large eaves block direct mid-day sun, high in the sky. The north side of the house is partially built into the hillside, insulating the home, keeping the temperature constant throughout the seasons. Future plans may add solar hot water or solar electric to power the house, and the garage is purposefully oriented for these features to be added at a later date.